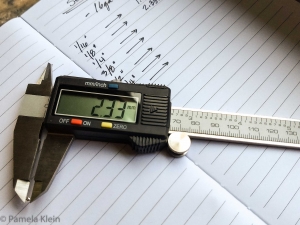

CHART: Sizes of Silver Granules

A Journal Entry on Making Silver Balls for Jewelry

Many people in my classes have heard me suggest using a journal for their jewelry designs and techniques. When it comes to certain techniques, journalling your methods and results can make future projects quicker and less wasteful. For instance, I always journal my etching projects, jotting down chemical strength, time lapsed, depth of the etch, and the finishing process. This has made the somewhat lengthy and involved chemical process much more manageable over the years.

Recently, in an Introduction to Soldering class, we talked about making little silver balls, or granules, that can be used to embellish future projects. The size of the ball created depends on the amount of metal used. This is a perfect occasion to journal some results, so last week I decided to practice what I preach and got to work.

What follows are some tips and techniques on making silver granules and the results I got regarding the length and gauge of wire and the size of the balls I created.

Technique (Couldn’t be Easier)

- Cut a piece of sterling or fine silver wire.

- Heat it with your torch on full heat until it balls up.

Tips

- Fine silver works better than sterling silver. Sterling silver (925) tends to develop little pock-marks in the surface, while fine silver (999) usually creates a nice smooth ball.

- Any soldering surface will work but I like a charcoal brick best for making silver granules.

- As the silver granule cools, it will usually sink a little into the soldering surface creating one flat side. This is handy for soldering the ball onto a flat surface in the future.

- If you prefer a more perfect sphere, with no flatness, use a bur shaped tool to carve out a little rounded divot in your soldering surface and create your ball in that “hole.” This way when the silver granule cools, it will conform to the domed shape of the hole, making a more perfect ball instead of going flat.

- The chart below reflects my journal entry using 16ga fine silver wire. If you use a different gauge, your results will be different. For very tiny granules you’ll need to use 18ga or smaller.

CHART

Silver Granules/Balls

Using 16ga Fine Silver Wire

1/16″ wire = 1.85mm dia.

1/8″ wire = 2.33mm dia.

1/4″ wire = 2.67mm dia.

3/8″ wire = 3.04mm dia.

1/2″ wire = 3.41mm dia.

3/4″ wire = 3.97mm dia.

1″ wire = 4.46mm dia.

This is so amazingly helpful, Pam! Thank you for doing this experiment AND for sharing your findings and bits of wisdom with us! You are a true Teacher. I am so deeply grateful.

Hope it comes in handy with an upcoming project!

Love the chart. Now I just need to work on my sweat soldering technique so I can get those cute balls to stay put

Glad to hear the chart is helpful. Next time you’re in class we should solder some balls to your piece! You can do that in the Nov 17th Open Studio if you’re interested in joining us.

Thank you,

you have explained these methods in a very simple words; and technically just as detailed way..!

Tips & chart are very useful..!